This controller uses two temperature probes for accurate home beer brewing system. L shape long probe is placed in the beer to accurately measure the liquid/beer temperature; the small probe is placed in the chiller (outside of the tank). This probe is to set the boundaries for heating and cooling, so that the chiller does not become too cold or too hot during the operation.

This dual-probe controller provides higher precision control compared to

the single-probe controller. The single-probe controller has some

limitations: If the probe is placed inside of the liquid, the outer layer

of liquid might get too cold during cooling, because the liquid cools much

slower than the air surrounding it. During heating, the outer layer of liquid

might also get too hot. If the probe is placed in the chiller (outside of

the tank), you may not know the true temperature of the beer

inside because the fermentation is an exothermic process. This

dual-probe controller is designed to solve this issue. For example, if

you set the temperature of fermentation in 14C degrees, you can set the boundary (chiller

temperature for probe 2) at 9C degrees. So the temperature in the chiller will

never go lower than 9C degrees during the cooling process. In

addition The controller equipped with high and low alarm set point that when

the temperature reach to alarm set points, the controller start beeping and

flashing.

The controller has two outputs. One for heating and another for cooling.

Utilizing both cooling and heating device control, refrigerators can be

controlled at specific temperatures regardless of the environmental climate.

This mini Temperature Controller is an excellent,

reliable, accurate and convenient multifunction device when you need to control

the temperature precisely and constantly. It’s suitable for all equipment which

need to control one zone or two zone (separately) for heating or cooling mode.

It is an ideal solution for a wide range

of professional applications to automatically control temperatures of up

to -50 to 120 °C. It comes with two temperature sensors and manual.

Features:

2 relay and 2 sensors with 2 independent zones

temperature controller.

2 zones (2 Heating mode, 2 Cooling mode or 1

Heating and 1 Cooling).

2 color display (red and blue) for each zone.

Control temperature by setting the start and stop

temperature setting value.

High and Low Alarm function (buzzer and flash

alarm).

Refrigerating control output delay protection for

Out1 and Out2.

Temperature calibration for each sensor.

Setting memory and factory default setting option.

Technical Parameters:

Temperature measuring range: -50-120 °C

Accuracy: 0.1 Celsius

Power consumption< 3W

Sensors: Two NTC 10K with 1m wire length

Power supply: AC 100-240V

Output: 2 outputs with 10 Amp load

Temperature sensors Specification:

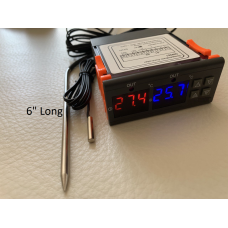

1-Stainless Steel L shape Sensor:

Measurement range: -50 to 120 °C

Cable length (L): 10 ft (3m)

Sensing tip material: Waterproof Stainless Steel L

shape sensor

L shape dimensions: 6"x2" (150mm x 50mm)

Sensor type: Negative Temperature Coefficient

Sensor

Type: 10K Ohm=25℃ B=3435

2-Sensor

Stainless Steel cylindrical:

Measurement range: -50 to 120 °C

Cable length (L): 3.3 ft (1m)

Sensing tip material : water proof stainless

steel sensor

Sensing tip length x diameter: 20mm x

5mm

Type: 10K Ohm=25℃ B=3435

Sensor type: Water proof Negative Temperature Coefficient sensor (NTC 25 °C=10k )

Beer Brewing Fermentation Curing Room Temperature Controller (Thermostat) with 2 sensors for Cooling and Heating and home-made Wine, Cider,...

- Product Code: DIN301-B

- Availability: In Stock

-

USD32.50

Related Products

Temperature Controller (Thermostat) for Beer Kegerator Chest Freezer Keg Tap Keezer with 2 sensors

DIN301 Two Zone Mini Temperature Controller Thermostat for Beer Kegerator.This is what you nee..

USD27.50

Temperature Controller (Fahrenheit) - 12V DC/AC for Solar Heating Water Fan Car Boat Cooler Hot Cold Warmer Fridge

This mini Temperature Controller (Fahrenheit display) is an excellent, reliable, accurate and conven..

USD32.50

PID Kit for Beer Brewing with (Programmable Ramp & Soak controller, RTD sensor, SSR 40Amp)

Make your own Beer Brewing system, by using this very economical & applicable kit. &n..

USD125.50

Temperature Controller with High Relay Contact Capacity of 30 Amps for Beer Kegerator °F °C

Mini Temperature Controller Thermostat for Controlling temperature on any device like Fan ventilatio..

USD44.50

Temperature Controller with High Relay Contact Capacity of 30 Amps for Pet Animal Dog Cat Reptile

Dual Mini Temperature Controller Thermostat for Controlling temperature on any Heater or Cooler devi..

USD44.50

Temperature Controller with High Relay Contact Capacity of 30 Amps for Coffee / Espresso Brewing Fahrenheit and Celsius

Mini Temperature Controller and Economical Temperature Controller with Washer Type Probe a..

USD44.50

Plastic ABS IP65 Enclosure Waterproof Dust proof Sealed Housing Case Electronic Electrical Project Big Box with 3 Glands

Plastic ABS Enclosure Project Box & 3 Cable Glands 4-8mm &nb..

USD15.50

Plastic NTC (Negative Temperature Coefficient) Sensor 10K Ohm Thermistor Water Proof Probe

It will work in water like aquarium, water tank,... Specifications: ..

USD7.50

NTC (Negative Temperature Coefficient) Sensor 10K Ohm Thermistor Cylinder Probe for Dish Washer Washing Machine Dryer

Specifications: Measurement range: -58 to 302 °F (-50 to 150 °C) ..

USD6.50

NTC (Negative Temperature Coefficient) Sensor 10K Ohm Thermistor Copper Washer Type Probe

This fast response washer sensor has a wide range of application and easily install in every p..

USD8.50

NTC (Negative Temperature Coefficient) Sensor 100K Ohm Thermistor Probe

It will work in water like aquarium, water tank,... Specifications: ..

USD7.50

Scientific Decimal Digital Thermometer K Thermocouple Celsius Fahrenheit with big LCD

Decimal Display Digital Thermometer up to 1300 °C 100% Brand new, High performan..

USD32.50

Spa Hot Tub Jacuzzi Pool Water Temperature Screw type Sensor Probe

Specifications: Measurement range: -58 to 230 °F (-50 to 110..

USD9.50

Professional Digital Infrared IR Non Contact Laser Gun Thermometer Pyrometer with adjustable Emissivity from 0.01 to 1 for HVAC, Auto, Electronic, Food services

Professional Digital Gun Infrared IR Thermometer Laser HVAC FºC with Adjustable Emissivity&..

USD26.50

Temperature Controller Thermoelectric TE Cooler TEC Peltier Laser Air cooling 12V

This mini Temperature Controller is an excellent, reliable, accurate and convenient multi function d..

USD43.50

Temperature Controller (2 Zone Thermostat) Cooling or Heating for Pet Animal Dog Cat Reptile Bird Reptile Chick Egg Incubator with High and Low Alarm

Two zone Temperature ControllerSome animals like Reptiles are cold-blooded animals, so they are unab..

USD27.50

Temperature Controller Thermostat Fahrenheit 12V DC Builtin Relay Freezer Heater

This mini Temperature Controller (Fahrenheit display) is an excellent, reliable, accurate and conven..

USD32.50

NTC Sensor 100K with Stainless Steel Braided wire Cover, internal fiberglass lead wire cover and Tinned Copper 10mm Washer Tip

Introducing our Temperature Sensor 3m (10ft), which boasts a temperature range of 0 to 300°C and a ..

USD14.50

NTC (Negative Temperature Coefficient) Sensor 10K Ohm Thermistor Stainless Steel L shape & Pin Point Tapered Probe

Temperature Sensor Probe 3m (10ft) with temperature range of (-50 to 150°C) This ..

USD11.50

Plug & Play Sous Vide Temperature Controller Thermostat Machine Slow Rice Cooker Crock Pot

This plug and play temperature controller with L shape SS braided wire, has a wide rang..

USD83.00

Plug & Play Temperature Controller (Thermostat) Cooling or Heating for Pet Animal Dog Cat Reptile Aquarium Bird Chick Egg Incubator

This heavy duty plug and play temperature controller with temperature sensor, has a wide range of ap..

USD75.00

Temperature Controller Thermostat Cheese Fridge Cheese making cave Freezer Chest Fermentation with 2 sensors

Dual Mini Temperature Controller Thermostat for converting any chest or freezer into accurate cheese..

USD27.50

Water Proof Radiant Floor Heat Temperature Probe 10K for Aube Floor Sensor AC112-01 Honeywell

Specifications: Measurement range: -58 to 302 °F (-50 to 150 °C) ..

USD7.50

Screw Probe for Thermistor Temperature Sensor Hayward GLX-PC-12-KIT 10K or Pentair 10K GOLDLINE AQUA LOGIC SALT Replacement

Water Temperature Sensor Probe with 3m (10ft) wire compatible with Hayward GLX-PC-12-KIT 10K or Pent..

USD9.50

Plug & Play Temperature Controller for Bird Chick Egg Chicken Coop Incubator Brooder

This heavy duty plug and play temperature controller with temperature sensor, has a wide range of ap..

USD75.00

Two Zones Temperature Controller Digital Thermostat for Heating and Cooling Equipment

DIN301 Two zone Temperature ControllerThis mini Temperature Controller is an excellent, reliabl..

USD27.50

Temperature Controller Make Coffee Bean Roaster Machine°F°C Temp Control Roast

Mini Temperature Controller and Economical Temperature Controller For Roasting Coffe..

USD39.50

Temperature Controller Fahrenheit Celsius with Timer up to 572°F 300°C & 0.1 Degree Control Accuracy & Buzzer Alarm

Controlling the temperature and time at the same time is a key to make accurate cont..

USD39.50

Plastic ABS IP65 Enclosure Waterproof Dust proof Sealed Housing Case Electronic Electrical Project Box with 3 Glands 200x120x75mm ( 7 3/4 x 4 3/4 x 3" )

Plastic ABS Enclosure Project Box & 3 Cable Glands 4-8mm &nb..

USD14.50

2 Single Zone Temperature Controller Hot Runner Control 2 Output 15A for Water Heater Solar System Panel with 2 Sensor

Temperature Controller Thermostat for Solar heating water, Fan,.... with 2 temperature sensor (contr..

USD45.00

Hot Tub Spa Water Temperature Sensor fr Winer Jazzi Monalisa JNJ Ethink Kingston Medsa

Water Temperature Sensor Coolant Probe Gauge Switch 3m (10ft) with temperature r..

USD9.50

1/4" Plastic ABS NTC 10K Sensor fr Underfloor heat thermostat, Air, Refrigerator, Aquarium Waterproof Probe

The Sensor works with most thermostats (INCLUDING ALL "WARMUP" THERMOSTATS). Please check the resist..

USD7.99

Temperature Probe Sensor Thermistor for Blodgett Commercial Oven 18588 44-1117 with 2 1/2" long tip and Stainless Steel braided cable NTC 100K

This sensor has additional SS braided cover for protecting wire for heating and also cut and abrasio..

USD12.99

NTC (Negative Temperature Coefficient) Sensor 10K Ohm Thermistor Copper Washer Type Probe

This fast response ( copper washer connection )sensor has a wide range of application and easily ins..

USD7.50

Distribution Electrical Box Enclosure IP65 Clear Cover ABS Power Supply Electronic Electrical Junction project Box for Din rail Component Waterproof Dust proof Sealed Housing Case with 3 Glands 200x120x75mm ( 7 3/4 x 4 3/4 x 3" )

High Quality Material: The shell is made of ABS plastic, the cover is made of transparent PC, the se..

USD15.50

NTC (Negative Temperature Coefficient) Sensor 10K Ohm Thermistor for Air or Water Screw Type Probe

Specifications: Measurement range: -58 to 230 °F (-50 to 110..

USD9.50

BBQ Smoker Oven Stainless Steel braided L shape Pin Point Sensor NTC 100K Probe

Temperature Sensor Probe 3m (10ft) with a temperature range of (0 to 300°C) Th..

USD12.50

Temperature Controller for Making Home Sous Vide Cooking Machine (10 Amp)

This add include Temperature controller and water proof sensor for sous vide and submersible High te..

USD45.50

Temperature Controller for Making Home Sous Vide Cooking Machine (10 Amp)

Controlling the temperature and time at the same time is a key to make accura..

USD43.99

PID Kit for Beer Brewing (Temperature controller , RTD sensor, SSR 40amp)

Make your own Beer Brewing system, by using this very economical & applicable kit.This kit..

USD59.99

Waterproof Protection Window Cover Panel IP67 for Electrical Button Switch Circuit breaker Distribution Box

High-Quality Material: The shell is made of ABS plastic, the cover is made of transparent PC, and th..

USD16.50

Differential Temperature Controller Thermostat for Boiler System with 2 sensors

A differential temperature controller in a boiler system works by comparing the current temperature..

USD43.99

Waterproof Plastic NTC Sensor 10K with 2.5mm connector

It will work in water like aquariums and water tanks,... Specifications: ..

USD8.50